Jaimin Brahmbhatt Design And Analysis Of Crankshaft For Single Cylinder 4-Stroke Deisel Engine International Journal of Advanced Engineering Research and Studies- E-ISSN2249 8974 2. Changes reciprocating motion of pistons into rotating motion to drive propeller Constructed of chrome-nickel-molybdenum- steel May be one piece or as many as three separate pieces The propeller mounts to the front of the crankshaft using a spline taper or flange The crankshaft rotates within the crankcase and is supported by main bearing journals Crankshaft throws or.

Pdf Design And Analysis Of Crankshaft Used In Aerospace Applications And Comparision Using Different Materials

Crankshaft is one of the critical component for the effective and precise working of the internal combustion engine.

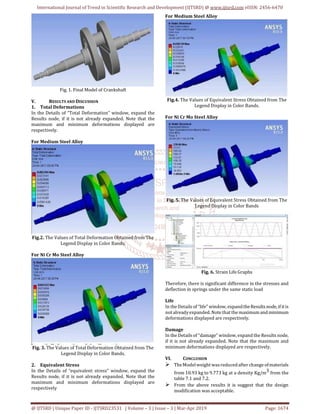

. A connecting rod basically connects the piston to the crankshaft whilst transmitting power of the combustion from the combustion chamber to rotate the crank. Then the results are drawn Von-misses stress induced in the crankshaft is 1583Mpa and shear stress is induced in the crankshaft is 8271Mpa. When it does not exist design it - Sir Henry Royce 3.

Simulation inputs are taken from the engine specification chart. The crank stress change model and the crank stress biggest hazard point were found by using finite element analysis and the improvement method for the crankshaft structure design was given. Thickness of crank web Tst 065 dc 635 dc Dia.

While in operations we have repaired over 10000 crankshafts of. Have experience of about four decades in crankshaft grinding engine repairs and maintenance. 21 st March 2011 Sakib Sarker Darlington Midrange Technical Operations MTO 2.

Finite element analysis FEA is performed to obtain the variation of stress at critical locations of the crank shaft using the ANSYS software and applying the boundary conditions. Analysis of crankshaft-cast Iron Figure- 71 Apply Boundary conditioon the crankshaft The two ends of the crankshaft is To be fixed the load 35 Mpa is applied on the top of the crankpin surface. There is absolutely no requirement of removing the crankshaft from the block and sending it to the workshop when RA Power Solutions is called into help support.

Take the best that exists and make it better. Our aim is to manufacture less expensive component with minimum weight and high fatigue strength. Figure- 72 crankshaft voin-misses stress The maximum stress induced in the crankshaft is 1583 Mpa at the crankpin neck surface.

Yu Ding and Xiaobo Li2011 Crankshaft Strength Analysis of a Diesel Engine Using Finite Element Method Asia-Pacific Power and Energy Engineering. Improvement in engine will. Design of Crank Web.

The crank web is designed for eccentric loading. DESIGN AND ANALYSIS OF CRANKSHAFT WITH DIFFERENT COMPOSITE PPTpptx - Free download as Powerpoint Presentation ppt pptx PDF File pdf Text File txt or view presentation slides online. Design of an Engine Crankshaft 1.

The static analysis is done using FEA software. Solve and find Diameter of Crank Pin. A three-dimension model of diesel engine crankshaft is created using Pro-E software.

DESIGN AND ANALYSIS OF A. Crankshaft Grinding and Repair Crankshaft Grinding Services - RA Power Solutions Pvt. 91-1244378292 4251615 Email ID.

91 9582647131 Tel No. Solve FBD for length. There will be two stresses acting on the crank web one is direct compressive stress and the other is bending stress due to piston gas load Fp.

Design and Validation of a Crankshaft 4. Design and development of crankshaft is major issue in industry because it is main power transmitting element.

Design And Analysis Of Crankshaft For Internal Combustion Engine

Design Of An Engine Crankshaft

Design And Analysis Of Crankshaft With Different Composite Pdf Deformation Engineering Young S Modulus

Design And Analysis Of Crankshaft For Internal Combustion Engine

Ppt Connecting Rods Powerpoint Presentation Free Download Id 1086711

Design And Analysis Of Crankshaft For Internal Combustion Engine

0 comments

Post a Comment